Defiantly Different: Tradition, Whisky, and the Blue Ridge Distillery

Redbud Lane in Golden Valley, North Carolina looks just like any number of small, gravel roads found anywhere in the country. But at the end of the lane is something that those other gravel road don't have: a distillery.

The red distillery building, at first glance, could be a barn, but when you look closer, you see the tall, wide doors made out of polished blond wood, and--peeking out from behind those doors--lots of shiny metal.

When I arrived onsite, I was greeted by Bill, one of the distillery's employees. "We built this building--the salvage guys and me--everything but the concrete floors," he tells me right off. And that's when I know that I'm not at your usual distillery. Bill, along with Tim Ferris, the owner, and several of the other employees, work as salvage divers when they aren't at the distillery. It's definitely an unusual combination, whisky and diving, but in so many ways, it reflects the ethos of the entire company.

They are different. They do things differently. And that's exactly how they like it.

Check Tradition at the Door

Defiant Whisky is the result of the company's commitment to make single-malt whisky through a non-traditional distilling process.

The process of creating Defiant Whisky begins with American-grown malted barley from Wisconsin. Water from a well on the property is added to the barley and heated. After this combination reaches the required temperature, the liquid from this mixture, called wort, is slowly siphoned off and then placed in one of the distillery's fermentation tank with yeast to create a barley wine.

Over the course of several days, the added yeast converts sugar to alcohol. If you added hops at this point, you'd get an American lager beer!

Next, the liquid goes into a still where it is heated to a temperature between the boiling points of water and alcohol. At the right temperature, the alcohol in the mixture will turn to vapor while the water remains a liquid. The distillers can control the number of times that the liquid goes through the distilling process: every time the liquid is distilled, it retains a higher alcohol content but loses flavor.

When the whisky has been distilled the correct amount of time to produce the desired flavor, the whisky is cooled down so that it becomes a liquid again.

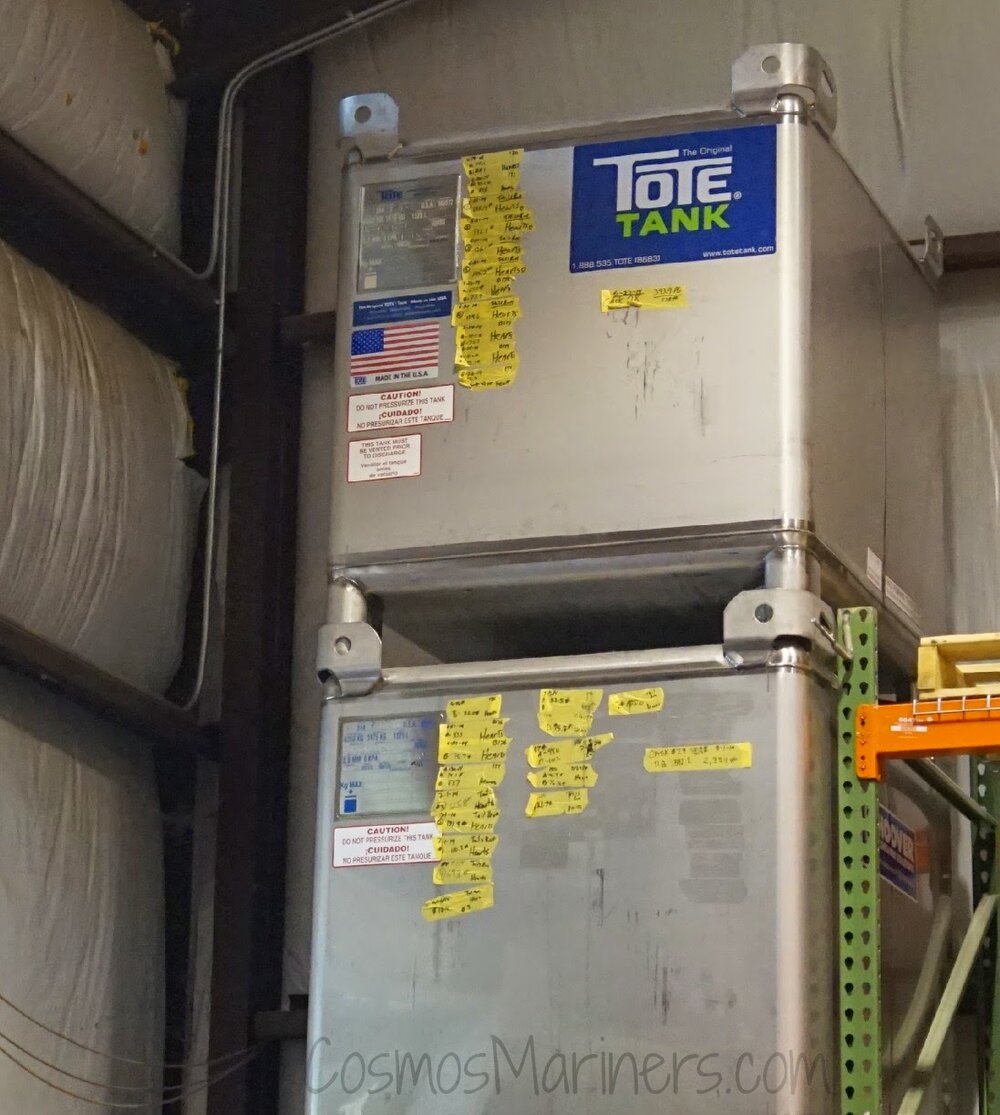

At this point, the whisky is drained from the still into a large milk jug; first, the heads of the whisky come out. These cannot be drunk (well, they can be but they aren't very tasty) since they have more of a medicinal taste. Then, the hearts of the batch come out--this is the good stuff! Finally, the tails of the batch come last: some distilleries add a bit of the tails to the hearts. The tails have a different taste than the hearts and, when added to the hearts, change the overall taste of the product. Defiant Whisky doesn't do this since they've worked hard on their product!

Up to this point, the process followed by the company is very similar to what you'd find at any traditional distillery. So, what do they do different?

Normally, traditional whiskies are put into an oak barrel. At Blue Ridge Distillery, the whisky is put into large metal tanks and hundreds of oak spirals are added to the liquid.

The distillers at Defiant have found that the oak barrel isn't necessary to getting the taste they want--it's the amount of surface area on the oak spirals that allows more of the whisky to interact with the oak cells. This chemical interaction adds to the final flavor of the drink and creates the flavor.

Elisa, one of the distillers, told me, "It's the maturation process that's important--not the age of the whisky." So, in other words, an 8 or 12 year whisky isn't better than a non-traditionally distilled whisky just because it's older.

So, once the whisky has reached the required level of interaction with the oak spirals, the finished whisky is placed in a bottling canister, where each bottle is hand filled and corked before being placed to the side to await its finishing touches--a label, a tag, and a quality seal on top.

In Defiant Whisky's process, the spirit goes from malted barley to bottled products on a pallet in about 90 days. And just as surprising, nothing is automated here. At every step, one of the handful of employees is there, mixing, draining, bottling, labeling, stacking.

World-wide, Homegrown

The man behind the whisky is Tim Ferris, the owner of Blue Ridge Distillery Company and a salvage diver. When I met him, I asked him about his experiences as a recovery diver, and he told me that he'd been on two jobs this year. The first was in Italy where he and his team recovered transatlantic cables from a shipwreck. The second was off the coast of Africa to recover equipment from a downed helicopter. In that situation, he had to train on land in an identical helicopter in order to figure out how things felt inside since there was zero visibility underwater. "I would feel something and I knew what it was," he said.

So, how did someone who works in the water end up distilling whisky in the North Carolina mountains? On his diving jobs, Tim sampled many of the world's greatest foods and whiskies, and he was inspired to try his hand at making his own version in between salvage jobs. The result from his experiments was Defiant Whisky; the location is Tim's family land. He decided to situate the distillery on the land after testing the water and finding that it had a pH balance perfect for the distillation process.

"Salvage divers are a non-traditional group," Elisa said, "So it's not surprising that we do things differently here."

Welcome to Camp Whisky

And do things differently they will.

The future for the distillery lies among the seventy buildings of a former Girl Scout camp. After Blue Ridge bought the camp this past summer, Tim and his team began to consider how they can make it into a place that would embody the company.

While part of the operation will remain at the current location, the camp will host portions of the distillation process, bottling, and shipping. There's also the possibility that Blue Ridge will use the camp's pavilion and main hall for entertaining visitors or for farm-to-table dinners using locally sourced produce and meat.

The company has plans to add in a 5000 liter to their current equipment, an addition that will allow the team to make in one day what it takes to do in a week currently.

Whether you look at what the distillery is doing in the short term, or the possibilities that Camp Whisky holds, there's no denying that Blue Ridge Distillery is going places. So, do yourself a favor, grab a glass, and taste the difference that going against the grain makes.

Have you ever gone on a distillery tour? What's your adult beverage of choice?